Here is a picutre of 14-16 S. Chapel in 1981. It was an all brick building that someone added the stucco and Prairie influenced porch to. In recent times, the apartments were never nice and only attracted desperate people.

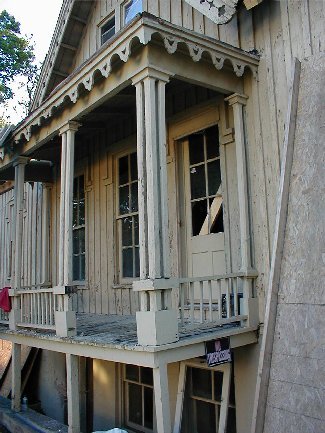

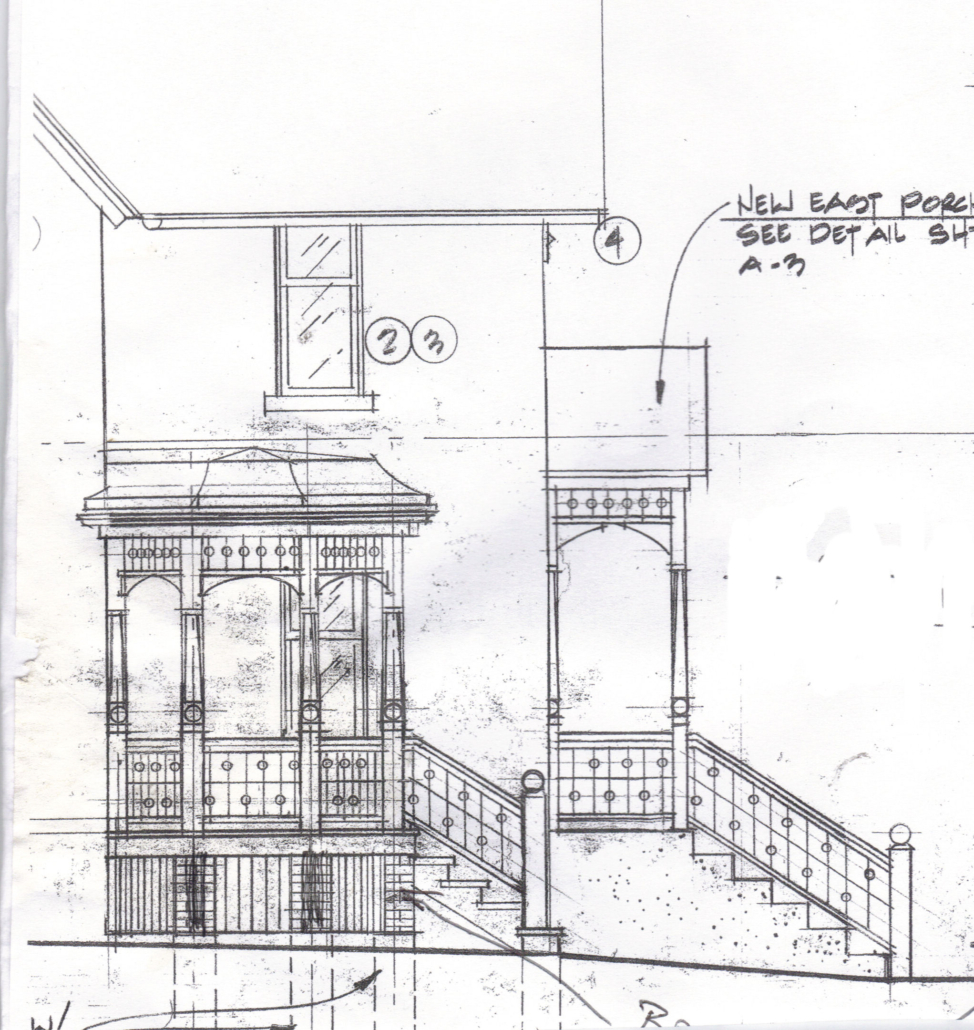

The Code Dept. cited a deteriorating porch so the owner, working with the city’s Preservation Planner replaced it with one appropriate to the age of the building. Here it is in 2008. The spindles and brackets in the frieze are store bought and too small. The interior and exterior of the building was not maintained so it fell into disrepair. A local investor bought the building and gutted it with the intention of rehabbing it. It stayed vacant for a couple of years. Recently two young investors purchased the building and have gone a long way in rehabbing the interior and exterior.

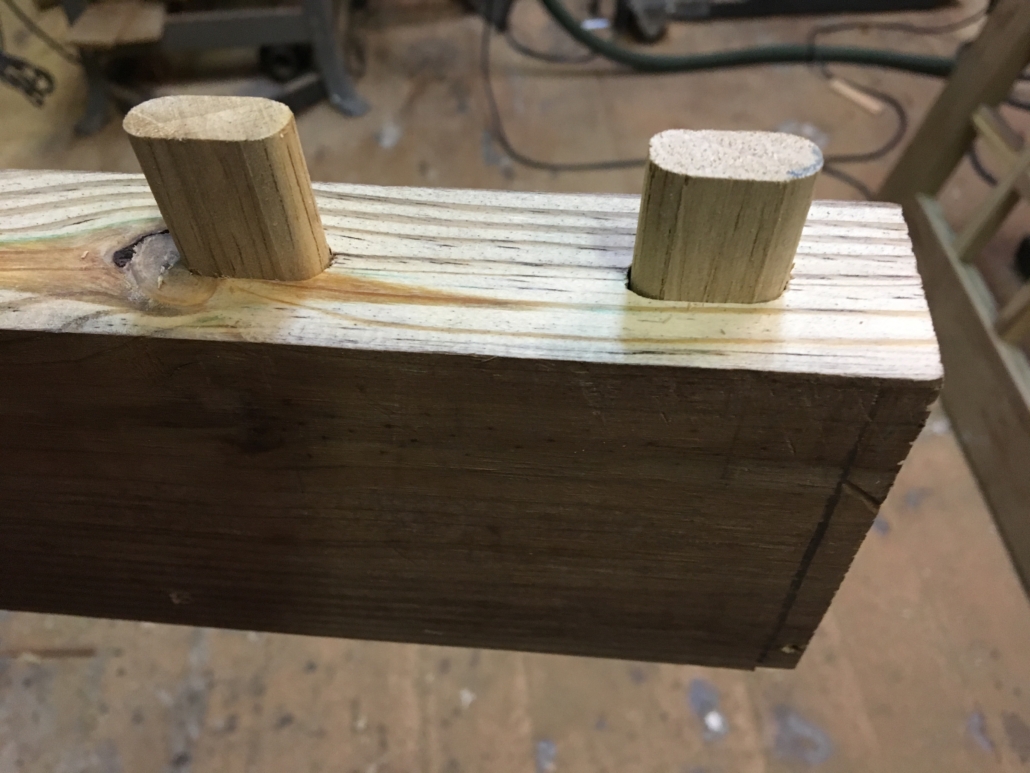

I had been working with the local investor to add an appropriate frieze and he agreed to allow me to chang it but then sold the building. The new investors contacted me and did allow to me make larger, approprote brackets but did not want to change the spindles as it would be very expensive. I also made stair treads for the front porch. I did not charge for my labor for the work but insted gave it to the new owners as a welcome to the neighborhood gift. Here are pictures of my brackets and the finished porch. The pattern for the brackets was taken from an actual bracket in Elgin. Th investors were helped with a 50/50 architectural grant.

The porch has an interesting tile floor.