Many parts of the porch at 150 S. Gifford were rotten or missing as seen at right. The owner was given several code violations forcing him to repair or rebuild it.

I proposed several different actual designs for the new balustrade. The one below came from a porch on Laurel St.

I proposed several different actual designs for the new balustrade. The one below came from a porch on Laurel St.

This is one from Gifford St.

This is one I saw in a magazine

Here is a variation of Laurel St. That Brian Anderson, the owner of one-third of the building proposed.

Christen Sundquist, the Preservation Specialist at the city made renderings of a possible design.

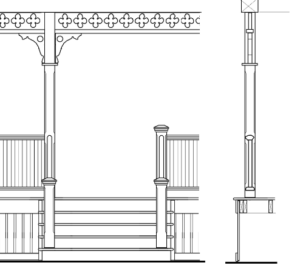

The owner decided to go with the Laurel St. variation. He hired an architect, which was dictated by the city, to draw up the plans as seen below.

The layout of the stair rail is difficult so my wife and I made a mockup to visualize it as seen below.

I made a full-scale mockup of the proposed balustrade as seen below at right and placed it on the porch, bottom left, so the owner could see it and give the approval to move on. It should have been lower but since the porch is so high off the ground by city code, it had to be 36 inches tall. The International Residential Building Code has a rule called the four-inch ball rule. It is to prevent kids’ heads from getting stuck in between two balustrades. If a four-inch ball can fit between two balusters, they are too far apart. My design needed six inches between balusters to look right. The IRC has a page that says the code can be modified for historic homes if it is not life-threatening. The city has bought into that idea but it still took months to get the variation for the proposed design.

The old porch was completely removed and new 48-inch deep cement piers were installed.

New framing was added using treated lumber. The carpenter made it very strong.

I pummeled the newels by first drawing circle patterns on the top and sides.

Here is the finished porch before it was painted and after. The finials are from Mr. Sppindle. I primed the flat boards on both sides to reduce shrinkage and warping. Treated lumber needs to be painted immediately or the sun and rain will make it twist and warp. I made the beadboard by making a custom molding knife to make the beadboard beads. It was milled from treated porch flooring. Pine beadboard is expensive and would rot away in five years. The decking and treads are Azec which will last forever. It looks almost like 1 X 4 porch flooring.

The owner received a 50/50 Architectural grant from the city which paid for half of the cost. He also received a $2000 Architectural grant from the Gifford Park Association.

While I was there I noticed that a squirrel had made a hole in the fascia. I made two pieces of custom crown duplicating the original exactly and had my handyman install them. Here is a picture of the hole, the original molding, and the molding I made in treated lumber.

I ground the wood off up to the line with an angle grinder as seen at right. A belt sander would also work.

I ground the wood off up to the line with an angle grinder as seen at right. A belt sander would also work.