The Saga of My Wood Lathe

In 1975 we inherited a nice rocking chair from my wife’s grand parents. It was missing a spindle. We looked everywhere for someone to make one spindle for us. We found places that would make 100 but not one. I was starting to get into woodworking as a necessity in rehabbing our first house so I decided to buy a lathe and turn it myself. The lathe cost $500 so my wife was not a happy camper as together we were only making $18,000 as teachers.

When I told a friend at work that I bought a lathe he literally laughed loudly at me saying that he knew all kinds of guys that had bought a lathe and then made a couple of salt and pepper shakers and never used it again. I vowed to prove him wrong and appease my wife.

Tom Ackeman and David Powers had converted a run down mansion that was being used as artists flophouse in the neighborhood into a private dining club called the Butterman’s. The rehab of this house was the first in a neighborhood and turned out to be an inspiration to others to do the same. I had noticed that the fancy porch was missing two spindles in the spandrel.

I went into the club and found Tom in the third floor lounge sitting back in a huge chair smoking a cigar and sipping a cocktail. I asked him if I could make the two spindles for him in exchange for a dinner for my wife and I. He jumped at the chance. I made the two spindles before reading anything about how to turn wood. I later found out that what I was doing was really scraping wood not turning it. There are two different spindles in the spandrel and I made one of each. Here it is today

We had a great dinner and the rocker was repaired so my wife was feeling a little bit better about my new expensive toy. I made friends with Tom and Dave and later did some intricate spindles for the interior balustrade. They had a wedding reception there and kids broke several of the spindles. I was paid well for the work.

This picture shows ones missing.

This picture shows my repairs. The spindles are small and oak so they were very hard to turn.

I read everything I could about wood turning and did several more jobs in the neighborhood for pay.

When my daughter came along in 1981 so I definitely wanted to use the lathe to make some toys.

The first one was a rattle that she never used as the handle  was too big to hang on to and it was too heavy for a baby. Making the rings was a challenge but luckily I had an article describing how to do it.

was too big to hang on to and it was too heavy for a baby. Making the rings was a challenge but luckily I had an article describing how to do it.

My mother used to put string thru a large button to create a toy. If you pull in and out on the string it spins the button. It was a lot of fun to play with. I made the same thing out of wood:

I made a wonderful spinning top

I glued maple and walnut together to make striped ball for the seal. The axle has a cam on it so the ball goes up and down when you pull it.

Since then I have made hundreds of interior and exterior spindles for old house customers. The most satisfying ones I have ever done were for a mansion at 4 N. Jackson in Elgin.

In the 70’s it was vacant and homeless people were living there. They took out several details to burn to stay warm. They took drawers made of quarter sawn sycamore which I also duplicated. Another thing they took were spindles from the grand staircase. They were missing all these years until I volunteered to make them.

It is common to find Tuscan column bases rotted. I have turned at least 50.

I turned turned 75 spindles for our own porch. The wood is glued up old growth cypress recycled from a water tower taken down in Chicago.

I turned the spindles for the porch across the street from us:

After the crash President Obama started a program called the National Stabilization Program. (NSP) Cities were given money to buy and rehab problem properties. Elgin received 1.2 million. I got to make the spindles for one. Thanks President Obama for spending taxpayer dollars in such a productive manner. Sure beats buying a new fighter jet!!!! For the cost of one jet hundreds and hundreds of problem properties were brought back across the nation.

As a volunteer I turned the balls for this porch balustrade on a house Habitat for Humanity rehabbed:

I have made hundreds of custom rosettes which are also called bullseyes for interior and exterior old house trim. I wrote an article for This is Carpentry on how to make custom rosettes.

I love round corner blocks on old house trim. It is not used very often. I only know of two houses in Elgin that have them and I got to duplicate some for both. You start by turning a big disk then cut in into four parts for the corner block.

of two houses in Elgin that have them and I got to duplicate some for both. You start by turning a big disk then cut in into four parts for the corner block.

The owner of the The Wing Mansion in Elgin had an old picture of his porch showing details that were now missing. I made the crosses with the chamfers and ball finial 0n top and the half balls.

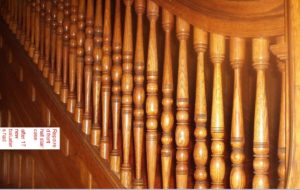

The most difficult job I have done is turning the parts for a missing  balustrade. A past owner had taken two sections of the balustrade down to put in a will for an apartment. I made all of the little pieces for the balustrade including hundreds of small turnings in oak. I also made the newel post and rail. This picture shows one of two sections I made.

balustrade. A past owner had taken two sections of the balustrade down to put in a will for an apartment. I made all of the little pieces for the balustrade including hundreds of small turnings in oak. I also made the newel post and rail. This picture shows one of two sections I made.

For 40 years I have turned wood into spindles, finials and column bases. I have never used a lathe duplicator and would often mention that those that use one are not really turning wood. A few months ago I finally broke down and bought one.

I spent as much for the duplicator as I did for the entire lathe back in 1979. I have used it twice. Once for large ball finials. Balls are typically hard to make look round on a lathe. With the duplicator I drew a perfect circle for the template and made a perfect circle every time. That was nice.

The only problem with the duplicator is that it cannot do fine lines so I have to touch up with lathe tools. I made the bead in the center of this ball with a skew, not the duplicator.

These were the first spindles I turned with the duplicator. The gray one is the original.

I made these finials for the same house before I got the duplicator. The one with paint is the original I duplicate the old fashioned way with calipers and lathe tools.