We bought our first old house in 1975 only because that was all we could afford. I calculated what I could afford and it was $30,000. This one cost $29,500. With 10% down my monthly payment was $250. At the time it was tough to make the payment as a teacher I was only making$9000 a year. It had an ugly storm door on the front that hid the fancy inner door.

We started looking into options. I had seen pictures of fancy Victorian Screen doors so we decided to go with that. I was an amateur woodworker so I wanted to make my own. We also saw marks for a missing frieze at the top of the porch. Looking for a replacement for that started my forty year love and study of old house porches.

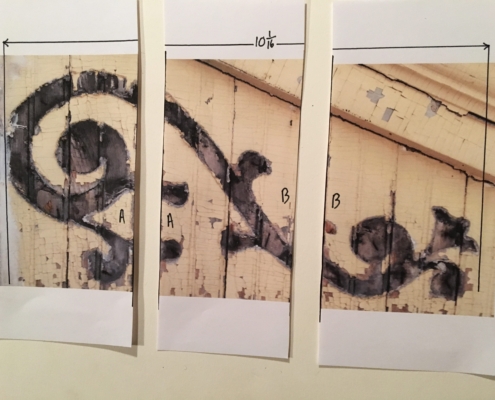

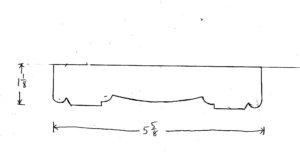

I wanted the door to be something that was authentic so whenever I saw a house with one on it I stopped and asked if I could trace and measure the details. After the people realized that I was not crazy they allowed me to do it. What would you do if a big ugly guy knocked on your door and asked to trace your details? I actually made some friends by doing it and one woman, after realizing what an old house nut I am actually invited me in for a complete tour. I found a real bracket that I used as a pattern for more and store bought spindles that would serve me well. I made my first Victorian Screen door even making mortise and tenon joints like the old timers did. They had huge machines to quickly and easily do it. Making them by hand as an amateur woodworker was not so much fun. I made a couple more like that then switched to making joints with large dowels. With a doweling jig it is much quicker. Most doors after the turn of the century were made with dowels instead of a mortise and tenon joint. Here is my first Victorian screen door and the frieze I made using a design I found on a house nearby. Marks for the spindles and middle pieces were left on our house.

Here is the seocnd door I made for our back porch. My doors have interchangeable storms and screens. The local glass place made them with aluminum frames. I put a rabbet on the inside of the door to accommodate them.

Here is the frieze and balustrade I made for the back porch to match the front:

Here are two I made for a neighbor.

The owner installed them himself. The door frames were not square so the doors required some planing which is very common. He did not want to do it so he took the door frames completely off and reinstalled them square so the doors fit perfectly without planing.

Here is anther one I made for a neighbor.

Below is another I made for a neighbor. This bracket pattern was taken from a door form a nearby house. The people had it in their garage and I convinced them to put it back up.

Here is the door I made for the back porch of our current house.

I made frames from wood for the interchangeable storms and screens. the frames and the doors have matching rabbets.

In the 70’s I became a Victorian Screen door nut. I wanted to be a missionary to spread the word about Victorian Screen doors. I took all of my authentic patterns and directions for making a screen doors including correct proportions and printed them in booklet form.

In the 70’s the Old House Journal let subscribers place ads in their magazine at no cost. I put an ad for my Victorian Screen door plan book in the magazine and sold over 500 of them nationwide at $5 each. Felt great. At the time there were not companies making them. There are several today but they are expensive and most do not look very authentic. I have now placed my plan book on line free to anyone that would like it. It has full size patterns for real brackets. Click here to see it.

A friend and neighbor had a great old picture of his house which originally had Victorian screen doors. He used a pattern from my booklet to make them. What a wonderful addition to our neighborhood.

Another friend and neighbor made these doors for his house.

A friend added store bought brackets to create a Victorian Screen door.

Here are more pictures of Victorian screen doors. The first on on the left is from Cape May, New Jersey. We visited there on our honeymoon in 1976.

If you make one for your house I would love to see a picture. Send it to Dan Miller at [email protected]

neighborhood for a long time. It looked bad as seen at right and had a lot of police calls. A flipper bought it and applied for downsizing and architectural rehabilitation grants from the city. He was set to get over $100,000 in grants to rehab the building. He gutted the interior, and tore off the aluminum siding and inappropriate porches. He then realized he was in over his head and stopped work. Soon after he got foreclosed upon. It sat as an empty eyesore for a few years. Another investor recently purchased the property and plans to live in half and rent the other. It has historically had two addresses one on Prairie and one on Chapel.

neighborhood for a long time. It looked bad as seen at right and had a lot of police calls. A flipper bought it and applied for downsizing and architectural rehabilitation grants from the city. He was set to get over $100,000 in grants to rehab the building. He gutted the interior, and tore off the aluminum siding and inappropriate porches. He then realized he was in over his head and stopped work. Soon after he got foreclosed upon. It sat as an empty eyesore for a few years. Another investor recently purchased the property and plans to live in half and rent the other. It has historically had two addresses one on Prairie and one on Chapel.

garbage picked the original front door when the house was being rehabbed. He gave it back to us.

garbage picked the original front door when the house was being rehabbed. He gave it back to us.

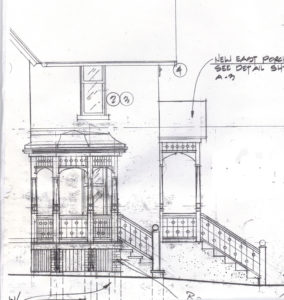

to do it again by buying another home to rehab for new offices. 205 N. Gifford was purchased for $40,000. It was a flophouse with padlocks on every door. The back stairs and basement were filled to the ceiling with junk as the owner was a pack rat. Volunteers filled two dumpsters to clean it out. An architect was hired to make exterior plans and specs for the inside. The first floor was to be the new NHS office and the second was to be rented out. This picture shows it shortly after the fake brick asphalt siding was taken off.

to do it again by buying another home to rehab for new offices. 205 N. Gifford was purchased for $40,000. It was a flophouse with padlocks on every door. The back stairs and basement were filled to the ceiling with junk as the owner was a pack rat. Volunteers filled two dumpsters to clean it out. An architect was hired to make exterior plans and specs for the inside. The first floor was to be the new NHS office and the second was to be rented out. This picture shows it shortly after the fake brick asphalt siding was taken off.

was too big to hang on to and it was too heavy for a baby. Making the rings was a challenge but luckily I had an article describing how to do it.

was too big to hang on to and it was too heavy for a baby. Making the rings was a challenge but luckily I had an article describing how to do it.

of two houses in Elgin that have them and I got to duplicate some for both. You start by turning a big disk then cut in into four parts for the corner block.

of two houses in Elgin that have them and I got to duplicate some for both. You start by turning a big disk then cut in into four parts for the corner block.

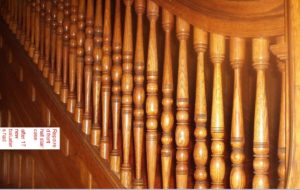

balustrade. A past owner had taken two sections of the balustrade down to put in a will for an apartment. I made all of the little pieces for the balustrade including hundreds of small turnings in oak. I also made the newel post and rail. This picture shows one of two sections I made.

balustrade. A past owner had taken two sections of the balustrade down to put in a will for an apartment. I made all of the little pieces for the balustrade including hundreds of small turnings in oak. I also made the newel post and rail. This picture shows one of two sections I made.